Weight Filling Machine

OK Corp designs a wide range of stainless steel automatic filling machines customized for your application. We manufacture these weight filling machines for a variety of dry solid products or for semi-liquid oils and fats such as margarine and shortening. We’ll usually combine these food filling machines with case erectors, bag inserters, bag closers, automatic weighing machines, case sealers and ancillary equipment to create automatic polybag-in-box systems.Here at OK Corp, we want to streamline your packaging process, and there’s no better way to do that than with our high-quality weight filling machines. No matter which sector of the food industry you’re in, our machines can help your packaging line run efficiently and safely! Work with us today so that we can design and manufacture the custom weight filling solution for you and your business. If you have any questions or would like to speak with our experts, reach out to us today.

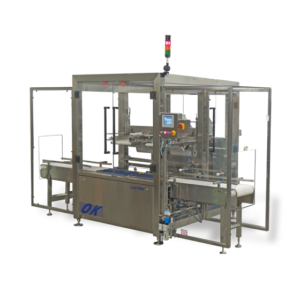

SUPERFILLER SR1

Automatic Weigh Filler Equipment for dry, solid products

The Superfiller SR1 machines are customized weigh fillers for solid products such as bakery products, candy, snack foods, nuts, rice, plastics, dried-fresh and frozen fruits or vegetables either by gross or net weight with belt or vibratory product feeders typically in a single lane or dual lane configuration.

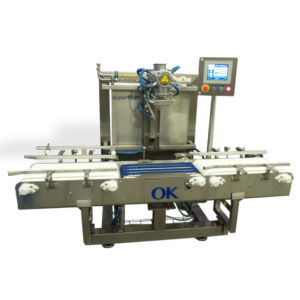

SUPERFILLER SR1L

Vibratory Weigh Filler for semi-liquids

The Superfiller SR1 is a Bulk Weigh Filler designed for semi-liquid oils and fats such as shortening and margarine. The single head configuration provides a cost effective solution for lower volume applications.

SUPERFILLER SR2/SR4

Weigh Fillers for semi-liquids

The Superfiller SR4 Bulk Weigh Filler is designed for semi-liquid oil and fats such as shortening and margarine. It is also available in a 2 head model (Superfiller SR2). These fillers are usually combined with automatic case erectors bag inserters, bag closers and case sealers to create automatic polybag-in-box systems suitable for high volume applications.

SUPERWEIGHER CW1/CW2

Check Weighers

The Superweigher CW1 & CW2 check-weighers are used to verify the accuracy of the filling process of products such as bakery goods, candy, snack foods, nuts, rice, plastics, dried/fresh and frozen fruits or vegetables and semi liquids such as shortening and margarine. These automatic weigh filling machines are available in single lane (CW1) or dual lane (CW2) configurations with or without reject system.

Superfiller SR1

Automatic Weigh Filler Equipment for dry, solid products

The Superfiller SR1 machines are customized weigh fillers for solid products such as bakery products, candy, snack foods, nuts, rice, plastics, dried-fresh and frozen fruits or vegetables either by gross or net weight with belt or vibratory product feeders typically in a single lane or dual lane configuration.

Features | Benefits |

High quality load cells. High quality load cells. |  Faster response time for higher accuracy and less product vie away. Faster response time for higher accuracy and less product vie away. |

Standard PLC controls. Standard PLC controls. |  No proprietary circuit boards, off the shelf components. No proprietary circuit boards, off the shelf components. |

Stainless steel. Stainless steel. |  Clean & Durable. Clean & Durable. |

Single source solutions. Single source solutions. |  OK International designs and manufactures complete polybag-in-box packing lines for your requirement. OK International designs and manufactures complete polybag-in-box packing lines for your requirement. |

TECHNICAL SPECIFICATIONS | |

| Configuration: | Gross- or net weight, belt- or vibratory product feeders, single or multi lane. |

| Fill Weight: | Typically from 4.5 – 45 kg / 10 -100 lbs. |

| Output: | Up to 11 tons/24,000 lbs./hour depending on product density and fill weight. |

| Accuracy: | 0.1% static accuracy. |

| Tare: | Pre-set or automatic tare of each container. |

| Controls: | Allen Bradley or Siemens PLC with touch screen display unit. |

| Construction: | Stainless Steel. |

| Conveyor: | Indexing conveyor with stops and clamps for positive container positioning. |

| Voltage: | 480v, 3 Phase, 60hz, or to requirement. 400v, 3 Phase, 50hz, or to requirement. |

| Air: | 80-100 PSI (6-8 bar), clean, dry and unlubricated air. |

Superfiller SR1L

Vibratory Weigh Filler for semi-liquids

The Superfiller SR1L is a Bulk Weigh Filler designed for semi-liquid oils and fats such as shortening and margarine. The single head configuration provides a cost effective solution for lower volume applications.

Features | Benefits |

Non-Drip Nozzle. Non-Drip Nozzle. |  Cleaner, more accurate process reduces cleaning, eliminates moving parts above the product and enhances product presentation. Cleaner, more accurate process reduces cleaning, eliminates moving parts above the product and enhances product presentation. |

Highest Quality Valves. Highest Quality Valves. |  3A Sanitary Valves, Polished 316 Stainless steel with quick removal connections. 3A Sanitary Valves, Polished 316 Stainless steel with quick removal connections. |

Analog digital load cell. Analog digital load cell. |  Fastests response time provides higher accuracy and less product give away. Fastests response time provides higher accuracy and less product give away. |

All stainless steel finish. All stainless steel finish. |  Clean & Durable. Clean & Durable. |

Converyor system. Converyor system. |  Variable speed conveyors with heavy duty case stops and clamps for fast and accurate case indexing. Variable speed conveyors with heavy duty case stops and clamps for fast and accurate case indexing. |

TECHNICAL SPECIFICATIONS | |

| Output: | Up to 8 tons / 17,500 lbs. per hour. |

| Fill Weight: | Typically from 10 -100 lbs. (4.5 – 45 kg). |

| Case Sizes: | To requirement. |

| Accuracy: | +/- two deviations of 20 grams. |

| Tare: | Pre-set or automatic tare of each container. |

| Controls: | Allen Bradley or Siemens PLC with touch screen display unit. |

| Fill Valve: | Highest quality, 3A sanitary valves, polished 316 stainless steel with quick removal connections. Jacketed optional. |

| Nozzle: | Non-drip nozzles, 3A polished 316 stainless steel. A drip catcher is usually not required but is available as an option. |

| Re-melt: | Extreme duty to position diverter valve to filler or re-melt. |

| Construction: | Stainless Steel. |

| Conveyor: | Indexing conveyor with stops and clamps for positive container positioning. |

| Voltages: | 480V, 3 Phase, 60Hz, or to requirement. 400V, 3 Phase, 50Hz, or to requirement. |

| Air: | 80-100 PSI (6-8 bar), clean, dry and unlubricated air. |

Superfiller SR2/SR4

Weigh Fillers For Semi-Liquids

The Superfiller SR4 Bulk Weigh Filler is designed for semi-liquid oils and fats such as shortening and margarine. This machine is also available in a 2 head model (Superfiller SR2). These fillers are usually combined with automatic case erectors, bag inserters, bag closers and case sealers to create automatic polybag-in-boxd systems suitable for high volume applications.

Features | Benefits |

Non-Drip Nozzles. Non-Drip Nozzles. |  Cleaner, more accurate process reduces cleaning, eliminates moving parts above the product and enhances product presentation. Cleaner, more accurate process reduces cleaning, eliminates moving parts above the product and enhances product presentation. |

Fill Valves. Fill Valves. |  3A polished 316 stainless steel with quick removal connections. 3A polished 316 stainless steel with quick removal connections. |

Analog digital load cells. Analog digital load cells. |  Fastest response time provides higher accuracy and less product give away. Fastest response time provides higher accuracy and less product give away. |

All stainless steel finish. All stainless steel finish. |  Clean & Durable. Clean & Durable. |

Full interlocked guarding. Full interlocked guarding. |  Operator safety and OSHA/CE compliant. Operator safety and OSHA/CE compliant. |

Automatic dual lane diverter conveyor system. Automatic dual lane diverter conveyor system. |  Variable speed conveyors with heavy duty case stops and clamps for fast and accurate case indexing. Variable speed conveyors with heavy duty case stops and clamps for fast and accurate case indexing. |

TECHNICAL SPECIFICATIONS | |

| Output: | Superfiller SR2 up to 12 tons/26,000 lbs./hour. Superfiller SR4 up to 18 tons/40,000 lbs./hour. |

| Line Speed: | 700 – 1400 cases per hour depending on fill weight. |

| Case sizes: | To requirement. |

| Accuracy: | +/- 2 deviations of 20 grams or better. |

| Tare: | Pre-set or automatic tare of each container. |

| Controls: | Allen Bradley or Siemens with touch screen display unit. |

| Valves: | Highest quality, 3A sanitary valves, polished 316 stainless steel with quick removal connections. Jacketed valves optional. |

| Nozzles: | OK International non-drip nozzles, 3A polished, 316 stainless steel. Drip catchers are usually not required but are available as an option. |

| Re-melt: | Extreme duty two position diverter valve to filler or re-melt. |

| Conveyors: | M600 stainless steel wash-down tabletop conveyor system or M1000 stainless steel washdown chain driven roller conveyor system, with diverter from single lane to dual lane and back. Variable speed conveyors with heavy duty case stops and clamps for fast and accurate case indexing. |

| Voltages: | 480V, 3 Ph, 60Hz, or to requirement. |

| Air: | 80 – 100 PSI (6 – 8 bar), 1/2″ supply clean, dry and unlubricated air. |

| Guarding: | Full guarding with in-feed and discharge tunnels. |

Superweigher CW1 / CW2

Check Weighers

The Superweigher CW1 & CW2 check-weighers are used to verify the accuracy of the filling process of products such as bakery goods, candy, snack foods, nuts, rice, plastics, dried/fresh and frozen fruits or vegetables and semi liquids such as shortening and margarine. These automatic weigh filling machines are available in single lane (CW1) or dual lane (CW2) configurations with or without reject system.

Features | Benefits |

High quality load cells. High quality load cells. |  Faster response time for higher accuracy and less product give away. Faster response time for higher accuracy and less product give away. |

Standard PLC controls. Standard PLC controls. |  No proprietary circuit boards. Off the shelf components. No proprietary circuit boards. Off the shelf components. |

Stainless steel finish. Stainless steel finish. |  Clean & Durable. Clean & Durable. |

Single source solutions. Single source solutions. |  OK International designs and manufactures complete polybag-in-box packing lines for your requirement. OK International designs and manufactures complete polybag-in-box packing lines for your requirement. |

TECHNICAL SPECIFICATIONS: | |

| Configurations: | Single or dual lane in-line or side by side. |

| Weight: | Typically from 10 -100 lbs. (4.5-45 kg ). |

| Accuracy: | 0.1% static accuracy |

| Container sizes: | To Requirement. |

| Controls: | Allen Bradley or Siemens PLC with touch screen display unit. |

| Construction: | Stainless steel wash-down |

| Conveyor: | Powered roller conveyor or tabletop chain conveyor. |

| Voltage: | 480V, 3 Phase, 60Hz, or to requirement. |

| Air (if applicable): | 80-100 PSI (6-8 bar), clean, dry and unlubricated air. |

See Our Machines in Action

Superfiller SR1 Dry Product Bulk Weigh Filler

Superfiller SR2/SR4 Semi-Liquid Weigh Filler

Superweigher CW1/CW2 Check Weigher

Options

Add these machines to create an automatic packing line:

- Superformer Case Erector

- Superliner Bag Inserter

- Supercloser Bag Closer

- Supertaper Case Sealer

- Conveyors

- Ancillary Equipment