In today’s fast-paced manufacturing world, staying competitive means constantly improving your processes. One area where companies can see significant improvements is in packaging operations. As demand for products increases and the need for efficiency grows, many businesses are turning to automated packaging lines. While the initial investment may seem substantial, the long-term benefits are numerous. Here’s why switching to an automated packaging line could be a game-changer for your business.

- Boosted Efficiency

One of the most obvious advantages of automating your packaging line is the increased speed and efficiency it offers. Unlike manual labor, which is subject to breaks, fatigue, and human error, automated systems work around the clock at a consistent pace. Machines can be programmed to handle repetitive tasks with a level of precision that humans simply can’t match, ensuring that packaging tasks are completed quickly and accurately.

This increased speed doesn’t just mean getting more products out the door—it also reduces bottlenecks and downtime. Automation ensures a smooth, continuous flow through the packaging process, minimizing interruptions and maximizing output.

- Significant Cost Savings

Although the initial investment in an automated packaging line might seem steep, the long-term financial benefits are undeniable. One of the biggest savings comes from reduced labor costs. Automation can eliminate the need for a large workforce to handle manual packaging tasks, and while some labor is still necessary for overseeing machines and troubleshooting, it’s far less than what would be required in a manual setup.

Additionally, automation reduces waste. Precise machinery can optimize material usage, cutting down on packaging waste and ensuring that products are packaged in the most efficient manner. This also contributes to cost savings in terms of raw material expenses, and over time, these savings add up.

- Improved Workplace Safety

The packaging process can involve tasks that are physically demanding or dangerous, such as lifting heavy objects, handling sharp tools, or working with high-speed machinery. Automation takes over these hazardous duties, reducing the risk of workplace accidents. With fewer employees performing physically intensive or dangerous tasks, companies can expect fewer injuries, which translates to lower workers’ compensation costs and improved employee morale.

By minimizing the exposure of workers to riskier aspects of packaging, businesses can create a safer, healthier work environment for their teams.

- Enhanced Consistency and Quality Control

Automated systems excel at maintaining high levels of consistency in packaging. Machines don’t suffer from fatigue or lapse in focus, meaning that every package is produced to the same high standard. For industries where product presentation and packaging accuracy are crucial, this consistency is vital.

Automation also plays a key role in quality control. Many modern automated systems are equipped with built-in sensors and monitoring tools that ensure every item is properly packaged. If a defect is detected, the system can flag it immediately, allowing for quick correction. This minimizes the risk of defective products reaching consumers, which helps protect the brand’s reputation and reduce costly recalls.

- Scalability to Meet Growing Demands

As businesses grow, so does the need to scale production. With an automated packaging line, scaling becomes much easier. If you find yourself facing increased demand or expanding into new markets, automation allows you to quickly ramp up production without having to hire additional labor. Simply adjust your system to meet new production targets—no need for a complete overhaul.

Moreover, the flexibility of automated systems means they can be reprogrammed to accommodate different product sizes, packaging styles, or seasonal spikes in demand. This versatility makes automated lines an excellent long-term investment for businesses looking to grow.

- Data-Driven Decision Making

Automated packaging systems are often equipped with sensors and connected software that gather valuable data on production performance. This real-time information allows businesses to track productivity, monitor equipment health, and identify areas for improvement. Predictive analytics can even help companies anticipate maintenance needs, preventing unexpected breakdowns that could lead to costly downtime.

With access to this wealth of data, companies are in a stronger position to make informed decisions about inventory management, production schedules, and resource allocation, further improving operational efficiency.

- Environmental Impact Reduction

As sustainability becomes an increasingly important issue for businesses and consumers alike, automated packaging systems can help reduce environmental impact. Automation optimizes packaging material usage, ensuring that every package is as efficient as possible. This not only reduces waste but can also support eco-friendly practices by utilizing recyclable or biodegradable materials.

In addition, automation can streamline packaging processes to minimize energy consumption, helping businesses lower their carbon footprint. When executed correctly, automated packaging is a win-win for both the bottom line and the environment.

- Employee Satisfaction and Retention

While automation can replace some manual labor, it doesn’t necessarily mean job loss. Instead, it frees up workers to focus on more meaningful tasks—such as quality control, machine maintenance, or process improvement. This shift allows employees to contribute in ways that utilize their skills more effectively, leading to higher job satisfaction.

Moreover, by reducing the physical strain of repetitive packaging tasks, automation helps create a more comfortable and engaging work environment. Employees are more likely to stay with a company that invests in their well-being and provides opportunities for professional growth.

- Faster Return on Investment (ROI)

The most significant obstacle for many businesses considering automation is the upfront cost. However, once the automated system is in place, companies can see a quick return on investment. Increased efficiency, reduced labor costs, and minimized waste quickly offset the initial expense, and as production volume grows, the savings continue to accumulate.

With careful planning and integration, the ROI from an automated packaging line can be realized faster than anticipated, especially in high-volume industries.

Conclusion

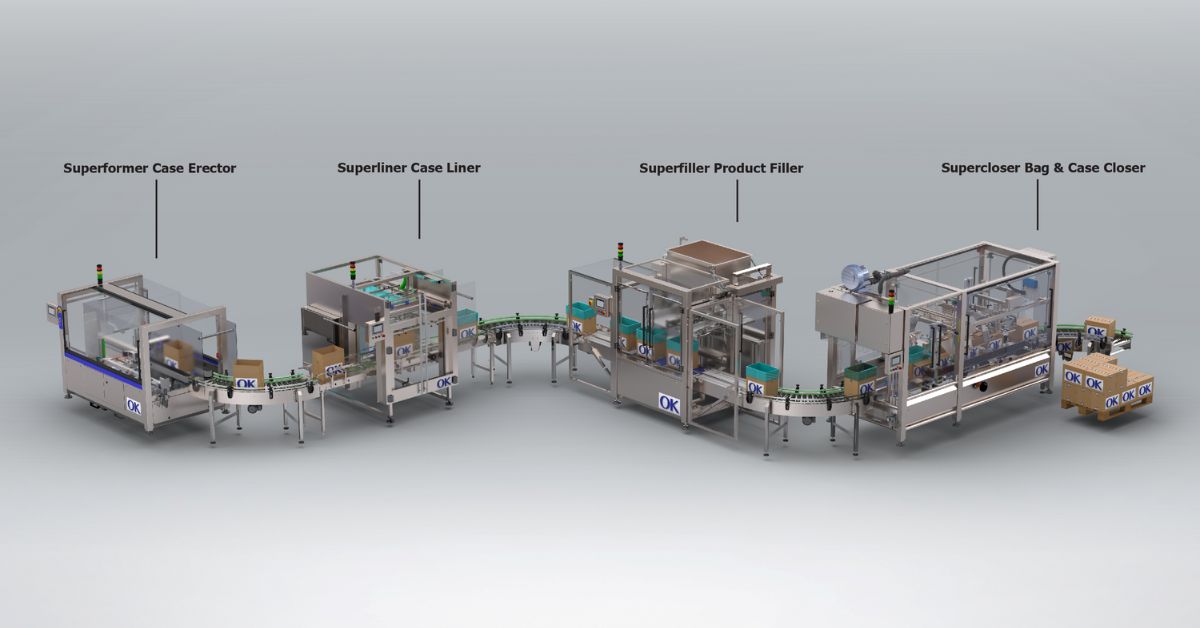

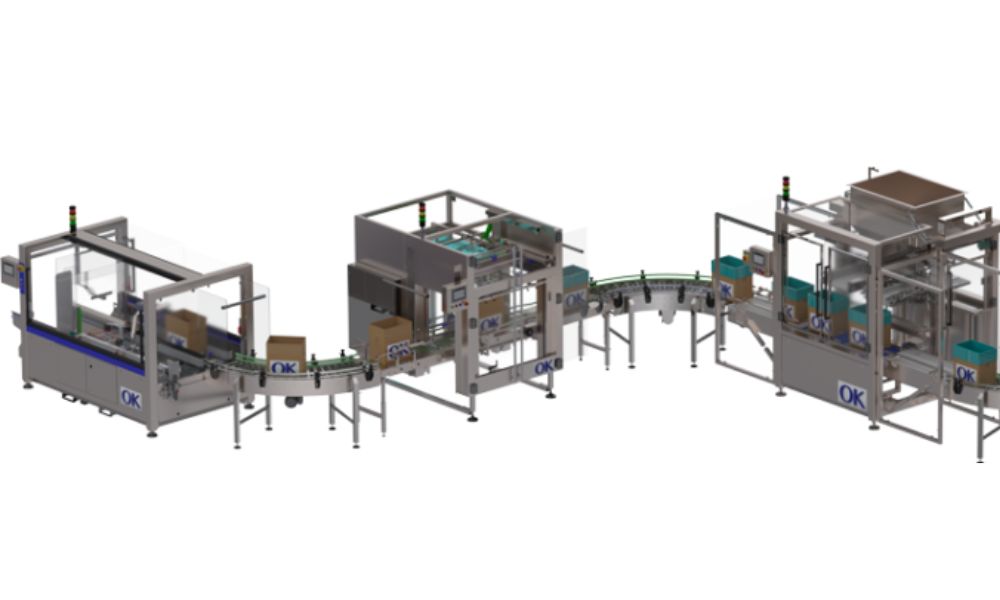

Incorporating automation into your packaging line is a smart investment for businesses looking to improve efficiency, reduce costs, and meet the growing demands of today’s marketplace. While the transition may require some upfront investment and planning, the long-term benefits—from enhanced safety to improved product consistency and scalability—are more than worth it. For many companies, automation isn’t just the future of packaging; it’s the key to staying competitive in an increasingly fast-paced, cost-conscious world. For your fully automatic packaging solution, please visit OK International Corp at www.okcorp.com for a complete overview of all of their end of the line packaging equipment they have to offer.