Fully automated End-of-Line Packaging Lines are an important investment. In today’s fast-moving manufacturing and distribution environment, the last thing your business needs is a bottleneck at the end of your production line. Manual case forming, filling, and sealing can slow operations, strain labor resources, and make it harder to hit growing demand targets.

That’s where a fully automated end-of-line packaging system featuring a case erector, case liner, filler, case sealer, and case taper becomes a game changing investment.

Below, we break down exactly how this type of packaging automation boosts efficiency, quality, cost savings, and long-term scalability for your business.

What Is an Automated End-of-Line Packaging Line?

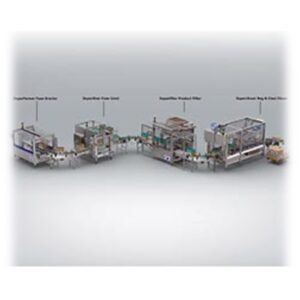

A complete packaging line typically includes:

- Case Erector – Forms flat cardboard blanks into perfectly square, ready-to-fill cases.

- Case Liner – Inserts protective liners or bags automatically where needed.

- Weigh Filler – Loads your product into the case with consistency and accuracy.

- Case closers – Automatically un-cuffs a filled polybag, opens the side flaps and folds the polybag into a neat two-way fold.

- Case Taper – Closes and seals the case using tape, glue, or other materials.

Together, these machines create a continuous, hands-off process from flat box to filled, sealed, shipping-ready case.

The Core Benefits of a Packaging Line for Your Business.

Massively Increased Output & Production Speed

Machines don’t take breaks, slow down, call out sick, or lose accuracy across long shifts. Automated lines typically:

- Produce 3–5× more cases per minute compared to manual staffing

- Reduce stoppages caused by fatigue, inconsistent folding, or rework

- Maintain steady, predictable output even during peak order periods

If growth is part of your long-term plan, automation ensures your packaging line can keep up.

Significant Labor Cost Reduction.

End-of-line packaging is one of the most labor-intensive areas of manufacturing. Automation allows you to:

- Reduce the number of workers required for repetitive box folding, filling, and sealing

- Reassign staff to higher-value positions like quality control or machine oversight

- Avoid seasonal labor shortages and expensive overtime

- Minimize injuries related to repetitive tasks and lifting

Over time, the savings in labor alone often offset the investment in automation.

Consistent, High-Quality Packaging.

When packaging is done manually, inconsistency is inevitable. Automation ensures:

- Perfectly square, correctly formed cases

- Uniform tape or adhesive application

- Properly positioned liners and accurate fills

- Dramatically lower risk of damaged or rejected cartons

This leads to:

- Fewer returns and product losses

- A more professional appearance in retail and shipping

- A stronger brand image in the eyes of customers and distributors

Reduced Waste & Operation Costs

Automation minimizes waste in multiple ways:

- Far fewer misformed or crushed boxes

- Optimized tape/glue usage with no excess application

- Reduced need for rework or repacking

- Lower product loss due to damage in transit

This translates directly into cost savings and a leaner operation.

Improved Workplace Safety

Manual packaging tasks involve bending, lifting, repetitive motion, and knife/cutter use, all major workplace hazards.

Automating these jobs helps:

- Reduce injuries and workers’ compensation claims

- Improve employee morale and retention

- Create a safer, cleaner, more organized production floor

Workers shift from repetitive labor to skilled operator roles, improving job satisfaction.

Scalability & Flexibility as Your Business Grows

Modern packaging lines are designed for flexibility:

- Quick changeovers between case sizes and SKUs

- Ability to integrate upstream or downstream equipment

- Modular design that grows as your business expands

Whether you’re launching new products or scaling into higher volume, automation ensures your packaging doesn’t become a bottleneck.

Cost Considerations & ROI of a Automated Packaging Line

A full end-of-line automated system is an investment but one that pays back fast.

Key savings areas include:

- Lower labor costs

- Reduced packaging waste

- Fewer product damages

- Higher throughput per shift

- Lower downtime and fewer errors

Most businesses see ROI in 12–36 months, depending on throughput and labor costs.

Is Automated Packaging Right for Your Business?

Automation is ideal for companies that:

- Are experiencing growth or planning to scale

- Need consistent packaging quality

- Struggle with labor availability or high turnover

- Want to reduce lead times and increase output

- Operate in competitive markets where efficiency matters

If your operation packages at moderate to high volumes, an automated line can transform how efficiently you run.

Automation Is Your Competitive Edge

A full automated packaging line, case erector, case liner, filler, uncuffer, and case taper, creates a packaging workflow that is faster, safer, more consistent, and far more cost-effective than manual methods.

It eliminates bottlenecks, reduces labor dependency, and prepares your business for long-term growth. Whether you’re looking to improve margins, enhance product appearance, or simply keep up with rising demand, packaging automation gives your business the competitive advantage it needs. For your fully automatic packaging solution, please visit OK International Corp at www.okcorp.com for a complete overview of all of their end of the line packaging equipment they have to offer.

Check Out our LinkedIn Post about this topic!