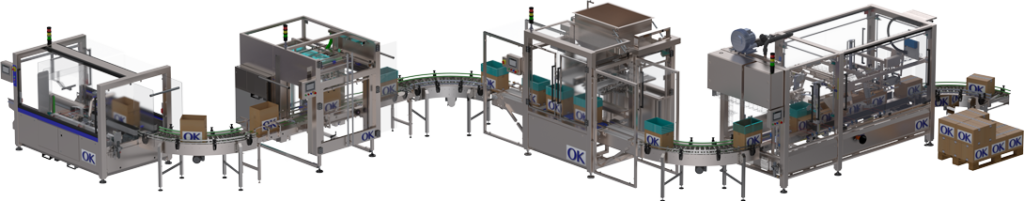

Customized End-of-Line Packaging Solutions

We custom design and manufacture the complete packaging line from case erectors and bag inserters to fillers and case closers in stainless steel.

Selecting and implementing the right packaging equipment systems for your packaging line can be a challenging process. With OK International, we can assure you that (with our team of experts) you can build and receive the optimal solution for your packaging line automation needs.

ABOUT US

OK International specializes in turnkey end-of-line packaging solutions for bulk product packaging needs. Our solutions include Case Erectors, Bag-in-Box Inserters (Case Liners), Liquid and Bulk Dry Product Fillers, Bag-in-Box Folders and Sealer Bag Closers, Case Closers (Case Tapers), Roll Stock Film, and custom designed Conveyors Systems.

Markets Served

(FIND YOUR INDUSTRY)