Superliner Polybag-in-Box Bag Inserter Machines

OKI is a world leader in the design, manufacturing and installation of Polybag-in-Box Bag Inserter Systems, around which we build complete Bulk Packing Line Solutions to meet the extensive needs of the market in numerous industries and applications. Our bag inserter machines eliminate the need for pre-made bags, resulting in a more efficient packaging line and fewer waste products. These polybag inserter machines make it easy to scale your operation with your company’s growth. They are simple to set up and begin operating while requiring only a minimal amount of maintenance and bag roll replacements. If your packaging line requires an automatic bag inserter, OK International offers you the best investment option you’ll find right here.SUPERLINER SL220

Polybag Maker & Bag Inserter

The SL220 makes bags from a roll of gusseted polyethylene tubing or handles pre-sealed bags on a roll, places the bag into a case, crate, drum or try and cuffs the bag over the edges to provide a hygienically lined container ready for bulk filling with a variety of food and non-food products. The machine is available in several versions including a Servo machine suitable for speeds of up to 24 cases per minute.

SUPERLINER SL330

Polybag Maker & Bag Inserter

The Superliner SL330 makes bags from a roll of gusseted polyethylene tubing and places the bag into a case, crate, drum or tray and then cuffs the bag over the edges. The SL330 is designed for customers using a wide range of film sizes and shipping containers requiring frequent changeovers.

SUPERLINER CL225

Case Erector & Case Liner

The Superliner CL225 is an integrated case erector and case liner that provides the best possible lining quality of bags inserted into electronically squared RSC or HSC cases at a rate of up to 15 cases per minute. The machine makes bags with an adjustable length from gusseted polyethylene tubing or uses pre-sealed bags on a roll. The CL225 is available with optional heat-seal assemblies for block bottom bags.

SUPERLINER SL230

Polybag Maker & Bag Inserter

The Superliner SL230 case liner makes bags from a roll of gusseted polyethylene tubing,

places the bag into a case, crate, drum or tray and cuffs the bag over the edges. Usually

integrated with a case erector or in a complete packaging line.

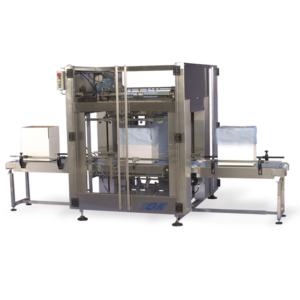

Superliner SL220

Polybag Maker & Bag Inserter

The SL220 makes bags from a roll of gusseted polyethylene tubing or handles pre-sealed bags on a roll, places the bag into a case, crate, drum or try and cuffs the bag over the edges to provide a hygienically lined container ready for bulk filling with a variety of food and non-food products. The machine is available in several versions including a Servo machine suitable for speeds of up to 24 cases per minute.

Features | Benefits |

Stainless steel finish. Stainless steel finish. |  Clean & durable. Maintains hygiene. Clean & durable. Maintains hygiene. |

Bags made on the machine. Bags made on the machine. |  Cost savings over pre-made bags. Cost savings over pre-made bags. |

Adjustable bag length. Adjustable bag length. |  Reduce inventory, one roll size makes multiple bag lengths. Reduce inventory, one roll size makes multiple bag lengths. |

Dual roll holder. Dual roll holder. |  Easy roll change with minimal down time. Easy roll change with minimal down time. |

Wide case and film range. Wide case and film range. |  Protects investment with flexibility for future market requirements. Protects investment with flexibility for future market requirements. |

TECHNICAL SPECIFICATIONS | |

| Case range: | |

| Superliner SL220: | 10.00” x 8.00” x 6.00” (L x W x H) min. 25.00” x 18.00” x 20.00” (L x W x H) max. |

| Superliner SL222: | 14.00” x 12.00” x 8.00” (L x W x H) min. 31.00” x 24.00” x 24.00” (L x W x H) max. |

| Speed per minute: | |

| Superliner SL220: | Up to 18 cases per minute. |

| Superliner SL220 SERVO: | Up to 24 cases per minute. |

| Superliner SL222 | Up to 15 cases per minute. |

| Bag materials: | All standard polyethylene films (HDPE, LDPE, LLDPE, co-extrusions.). |

| Bag gauges: | 0.7-3.0 mil (15 – 75 micron) depending on material. |

| Electric: | 480V, 3 Phase, 60Hz standard, or to requirement. 400V, 3 Phase, 50Hz standard, or to requirement. |

| Pneumatic: | 80-100 psi (6-8 Bar), 1/2” supply. Clean dry and unlubricated air. |

| Controls | Allen Bradley or Siemens with operator fault finding display. |

| Machine handling: | Right to left or left to right. |

| Finish: | Stainless steel, zinc plated. |

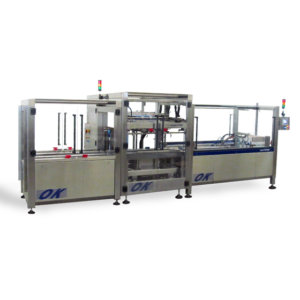

Superliner SL330

Polybag Maker & Bag Inserter

The Superliner SL330 makes bags from a roll of gusseted polyethylene tubing and places the bag into a case, crate, drum or tray and then cuffs the bag over the edges. The SL330 is designed for customers using a wide range of film sizes and shipping containers requiring frequent changeovers.

Features | Benefits |

Quick and easy size change. Quick and easy size change. |  Maximum productivity and flexibility. Maximum productivity and flexibility. |

Easy and fast roll change. Easy and fast roll change. |  Operator friendly loading of the rolls at an ergonomic without lifting the roll shaft, roll changes in seconds. Operator friendly loading of the rolls at an ergonomic without lifting the roll shaft, roll changes in seconds. |

High efficiency bag opening. High efficiency bag opening. |  High flow suction system, most efficient bag opening, no wear parts, maximum reliability and low maintenance. High flow suction system, most efficient bag opening, no wear parts, maximum reliability and low maintenance. |

Compact design. Compact design. |  Optimal case range at minimal floor space and machine height. Optimal case range at minimal floor space and machine height. |

Stainless steel finish. Stainless steel finish. |  Clean & durable finish preferred in food industries and harsh environments. Clean & durable finish preferred in food industries and harsh environments. |

TECHNICAL SPECIFICATIONS | |

| Container styles: | Cases, crates, drums, pails, trays. |

| Size range: | 10.00” x 8.00” x 4.00” (L x W x H) min. 24.00” x 18.00” x 20.00” (L x W x H) max. |

| Bag length range. | 16″ – 46″ (400mm – 1150mm) |

| Bag materials: | 0.7-3.0 mils (17-75 microns) gusseted tubing, made from standard polyethylene films (HDPE, LDPE, LLDPE, blends and co-extrusions.) |

| Roll holder: | Holds two rolls of film; low level loading direct onto the shafts, easy splicing and roll changes in seconds. |

| Roll diameter: | Up to 20.00” (500mm). |

| Speed: | Standard machine up to 18 cycles per minute. |

| Electric: | 480V, 3 Phase, 60Hz standard. Other voltages to requirement. 400V, 3 Phase, 50Hz standard. Other voltages to requirement. |

| Pneumatic: | 80-100 psi (6 – 8 bar), 1/2” supply. Clean, dry and unlubricated air. |

| Controls: | Allen Bradley or Siemens PLC controls with operator fault finding display. |

| Guarding | Full guarding with in-feed and discharge tunnels. |

| Finish: | Stainless steel. |

| Machine handling: | Right to left or left to right. |

Superliner CL225

Case Erector & Case Liner

The Superliner CL225 is an integrated case erector and case liner that provides the best possible lining quality of bags inserted into electronically squared RSC or HSC cases at a rate of up to 15 cases per minute. The machine makes bags with an adjustable length from gusseted polyethylene tubing or uses pre-sealed bags on a roll. The CL225 is available with optional heat-seal assemblies for block bottom bags.

Features | Benefits |

Integrated case erector, case liner and bottom taper. Integrated case erector, case liner and bottom taper. |  Ease of setup, training and operation. Ease of setup, training and operation. |

Suction box provides best possible lining quality. Suction box provides best possible lining quality. |  Hygienic; no parts are contacting the clean inside of the bag and maximum volume is available for product filling. Hygienic; no parts are contacting the clean inside of the bag and maximum volume is available for product filling. |

Automatic case squaring system. Automatic case squaring system. |  Consistency for automatic lines and enhanced cosmetics. Consistency for automatic lines and enhanced cosmetics. |

Bags made on the machine. Bags made on the machine. |  Cost savings over pre-made bags. Cost savings over pre-made bags. |

Adjustable bag length. Adjustable bag length. |  Reduce inventory, one roll size makes multiple bag lengths. Reduce inventory, one roll size makes multiple bag lengths. |

Tape, fillm and case monitoring. Tape, fillm and case monitoring. |  Operator friendly and higher reliability. Operator friendly and higher reliability. |

Stainless steel finish. Stainless steel finish. |  Clean and durable finish, preferred in food and other industries. Clean and durable finish, preferred in food and other industries. |

Dual roll holder. Dual roll holder. |  Ergonomic, low level, easy roll changes with minimal downtime. Ergonomic, low level, easy roll changes with minimal downtime. |

TECHNICAL SPECIFICATIONS | |

| Case range: | 10.00″ x 8.00″ x 6.00″ (L x W x H) min. 20.00″ x 16.00″ x 16.00″ (L x W x H) max. |

| Speed: | Up to 15 cases per minute. |

| Case Magazine: | Horizontal powered indexing case magazine, length 40” (1000mm) with rear pushers for easy loading of the cases. 60″ (1500mm) optional. |

| Taping head: | OK-55 high quality taping head with open tape feed path, suitable for 2” (50mm) wide tape and 14” (350mm) diameter rolls. OK 75 3″ (75mm) optional. |

| Bag Gauges: | 0.7 – 3.0 mil (17 – 75 microns) depending on material. |

| Bag material: | All standard polyethylene films. (HDPE, LDPE, LLDPE, blends and co-extrusions) |

| Roll Holder: | Holds two rolls of film; low level loading and easy splicing for quick roll changes. Roll diameters up to 19” (480mm) or 100 lbs. (45kg) max. |

| Electric: | 480V, 60 Hz, 3 Phase, or to local requirement. 400V, 50 Hz, 3 Phase, or to local requirement. |

| Pneumatic: | 90 – 100 psi (7-8 Bar), 3/4” supply. |

| Controls: | Allen Bradley or Siemens PLC controls with 6” color touch-screen display with self-diagnostics and troubleshooting. |

| Signals: | Low cases, no cases, low bags, no bags, bag not opened, low tape, no tape, tape not applied and tape not cut. |

| Finish: | Stainless Steel. |

| Machine handling: | Depending on case handing, right to left or left to right. |

Superliner SL230

The Superliner SL230 case liner makes bags from a roll of gusseted polyethylene tubing, places the bag into a case, crate, drum or tray and cuffs the bag over the edges. Usually integrated with a case erector or in a complete packaging line.

Features | Benefits |

Stainless steel finish. Stainless steel finish. |  Clean and durable, maintains hygiene. Clean and durable, maintains hygiene. |

Bags made on the machine. Bags made on the machine. |  Cost savings over pre-made bags. Cost savings over pre-made bags. |

Adjustable bag length. Adjustable bag length. |  Reduce inventory, one roll size makes multiple bag lengths. Reduce inventory, one roll size makes multiple bag lengths. |

Dual roll holder. Dual roll holder. |  Easy roll change with minimal down time. Easy roll change with minimal down time. |

Wide case and film range. Wide case and film range. |  Protects investment with flexibility for future market requirements. Protects investment with flexibility for future market requirements. |

TECHNICAL SPECIFICATIONS | |

| Case range: | 10.00” x 8.00“ x 6.00” (255x200x150mm) (L x W x H) min. 25.00“ x 18.00” x 20.00“ (635x460x500mm) (L x W x H) max |

| Speed: | Up to 15 cases per minute. |

| Bag Gauges: | 0.7 – 3.0 mil depending on material. |

| Bag material: | All standard polyethylene films. (HDPE, LDPE, LLDPE, co-extrusions) |

| Electric: | 480V, 60 Hz, 3 Phase, or to local requirement. 400V, 50 Hz, 3 Phase, or to local requirement. |

| Pneumatic: | 90 – 100 psi (7-8 Bar), 3/4” supply. |

| Controls: | PLC Controls with 6” (150mm) Color Touchscreen HMI. |

| Finish: | Stainless Steel, zinc plated. |

| Machine handling: | Depending on case handing, right to left or left to right. |

See Our Machines in Action

Superliner SL220 Polybag Maker & Bag Inserter

Superliner SL330 Polybag-in-box Maker & Bag Inserter

Superliner CL225 Case Erector and Case Liner

Superliner SL220 Case Liner Polybag Maker & Bag Inserter w/ Flap Fold Down System

Superliner SL220 Case Liner w/ Superformer SF1-HM-FOL

Superliner SL220 Servo Case Liner

Options

Customize your machine

- 45 Degree Angled Gusset Seals to Make Block Bottom Bags

- Bag Detect & Reject Systems

- Fold Down System for Case Top Flaps

- SL222 Machine for Larger Sizes

- SL220 Servo Machine for Higher Speeds

- Premade Bags on a Roll

Get in Touch with a Representative

We’re here to help you customize your machine.